Hook + Big Claim

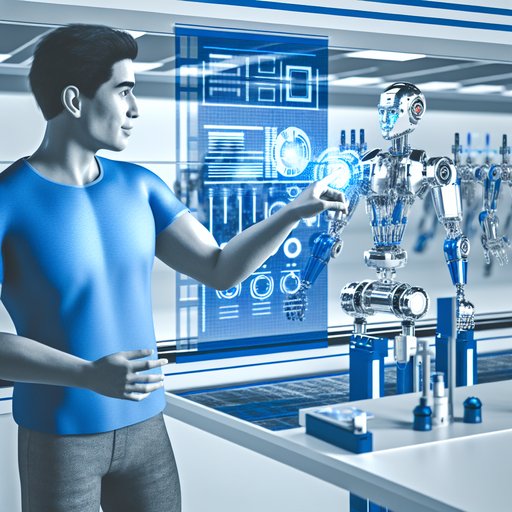

In the next few months, factories around the globe will witness a profound shift as robot-human collaboration transforms production processes. This evolution promises not just enhanced efficiency but also significant changes in the way factories operate, ultimately setting new standards for productivity and adaptability. As we navigate this transformation, understanding the implications of this partnership becomes essential for stakeholders across the manufacturing spectrum.

Current Landscape

Robots have long played a critical role in factories, particularly in tasks that are dangerous, repetitive, or require high precision. Companies like FANUC and ABB have pioneered the use of industrial robots, enabling advances in speed and accuracy. Recent years have seen a surge in more collaborative robots, or “cobots”, designed to work alongside humans. These cobots, with brands like Universal Robots leading the charge, are tailored to assist in tasks that require a human touch, such as assembly, inspection, and packaging.

Cobots are equipped with sensitive sensors and sophisticated software that allow them to safely interact with human workers. A prime example is the automotive industry, where cobots assist in assembling complex components, ensuring precision while maintaining safety standards.

What’s Changing and Why

Several factors are driving the rapid adoption and evolution of robot-human collaboration in factories:

- Advancements in AI: Machine learning algorithms enhance cobots’ abilities to learn tasks efficiently and adapt to new processes, making them highly versatile.

- Cost Reduction: As technology matures, the cost of deploying cobots is decreasing, making them accessible to small and medium-sized enterprises.

- Workforce Dynamics: With an aging workforce and skills shortages in specific sectors, cobots help fill the productivity gap without eliminating human jobs. Instead, they take over mundane tasks, allowing human workers to focus on complex and creative duties.

Predictions & Implications

In the upcoming months, several trends are expected to define the future of robot-human collaboration in factories:

- Increased Adoption Across Industries: Beyond automotive, industries like electronics, pharmaceuticals, and food processing will increasingly adopt cobots, driven by the need for precision and adaptability.

- Enhanced Safety Protocols: As cobots become more integral, safety standards will evolve to ensure seamless and safe human-robot interaction.

- Reskilling Initiatives: Companies will invest in training programs to equip workers with skills to oversee and collaborate with robotics, emphasizing a symbiotic relationship rather than a competitive one.

Final Takeaway

For companies looking to leverage robot-human collaboration in their operations, the key lies in strategic implementation. Businesses should prioritize integrating cobots in areas where humans and machines can complement each other. Investing in reskilling initiatives will also be crucial in fostering a collaborative environment.

As we look ahead, the factories that successfully merge human ingenuity with robotic precision will set the benchmark for innovation and productivity. Embracing this trend will not just redefine manufacturing but also reshape the future workforce dynamic, creating a more adaptable and resilient industry landscape.